What We Do

Carrabay offers complete supply and install services, including in-house rebar manufacturing, offsite prefabrication, and custom cage production. Our integrated approach combines labour and plant hire with full Form Reo Pour capabilities, ensuring efficient project delivery from start to finish. From complex tunnel builds and rail upgrades to large-scale infrastructure, bridges, mining, renewables and civil construction, Carrabay brings technical precision to Australia’s most complex construction environments.

From Factory Floor to Final Pour

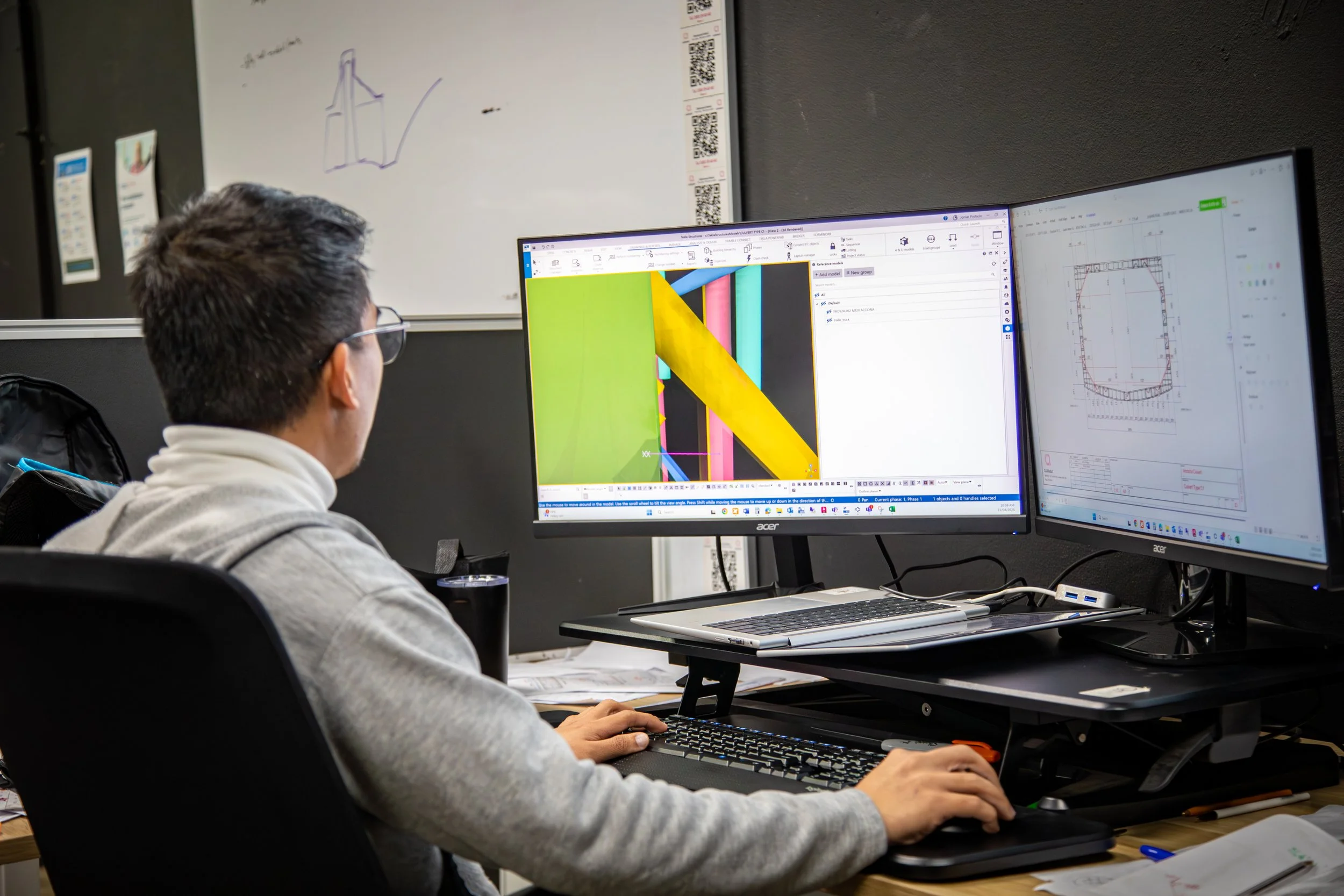

ENGINEERED SOLUTIONS

We drive innovation by collaborating closely with clients to deliver custom, value-engineered reinforcing solutions that tackle complex challenges and optimise material use. By resolving complexity in our factory instead of on-site, and engaging early through design-for-manufacture expertise, we identify efficiencies, mitigate risk, and streamline the entire reinforcing process from drawing board to final pour, optimising design and cost.

Supply & Install

We specialise in the installation and placement of reinforced steel and mesh for concrete structures, which remains one of our key service strengths. Our experienced labour force consistently delivers high-quality steel fixing solutions, supported by a dependable and well-coordinated team. With a strong reputation across Australia, we are recognised for our professionalism and attention to detail.

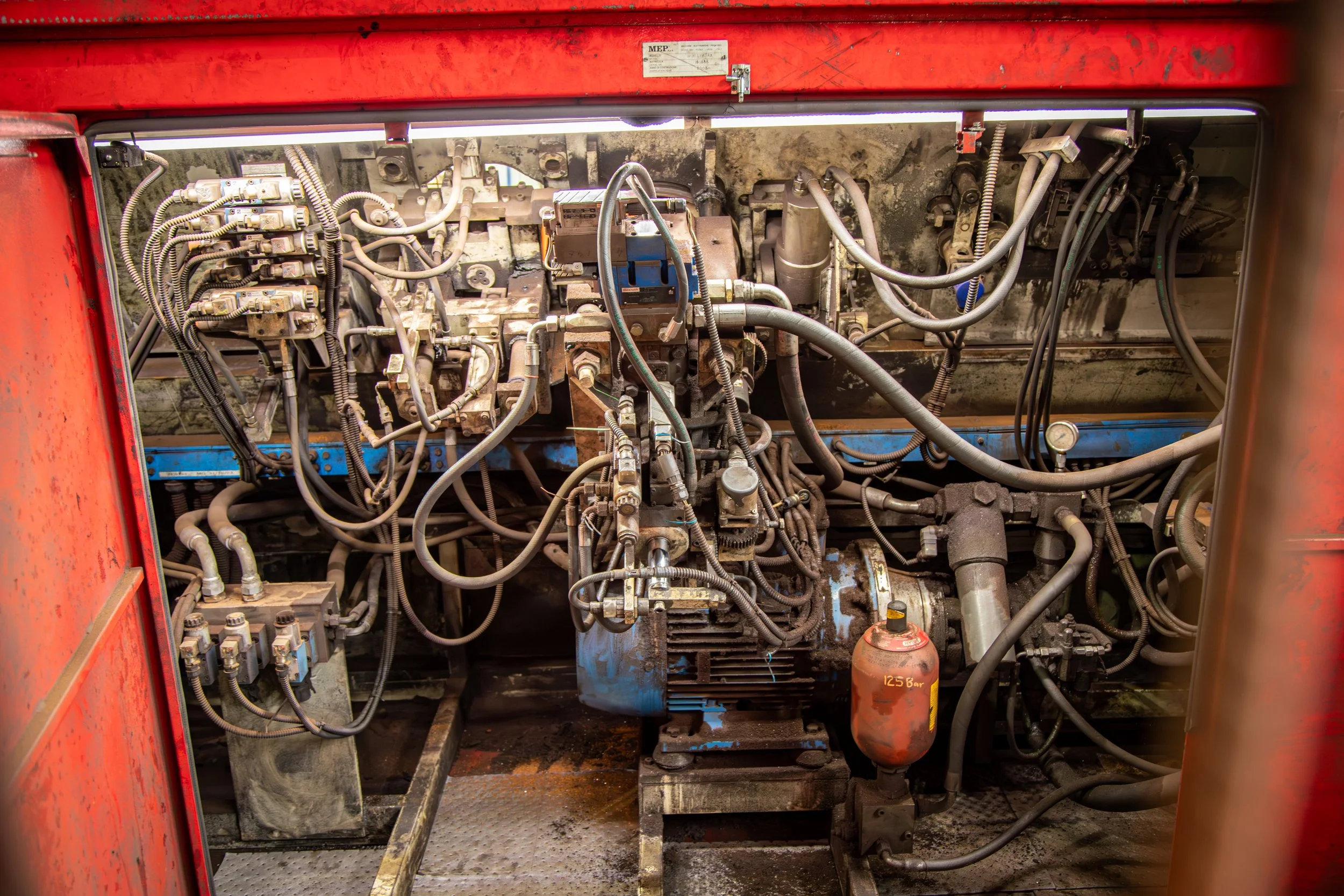

Rebar Manufacturing

We provide precision cut and bend services for reinforcing bar in a range of diameters, shapes and sizes, tailored to project specifications. All reinforcement is shaped and prepared in full compliance with Australian Standards, ensuring quality and consistency on site. Our rebar is sourced exclusively from registered Australian suppliers, guaranteeing traceability and alignment with industry requirements.

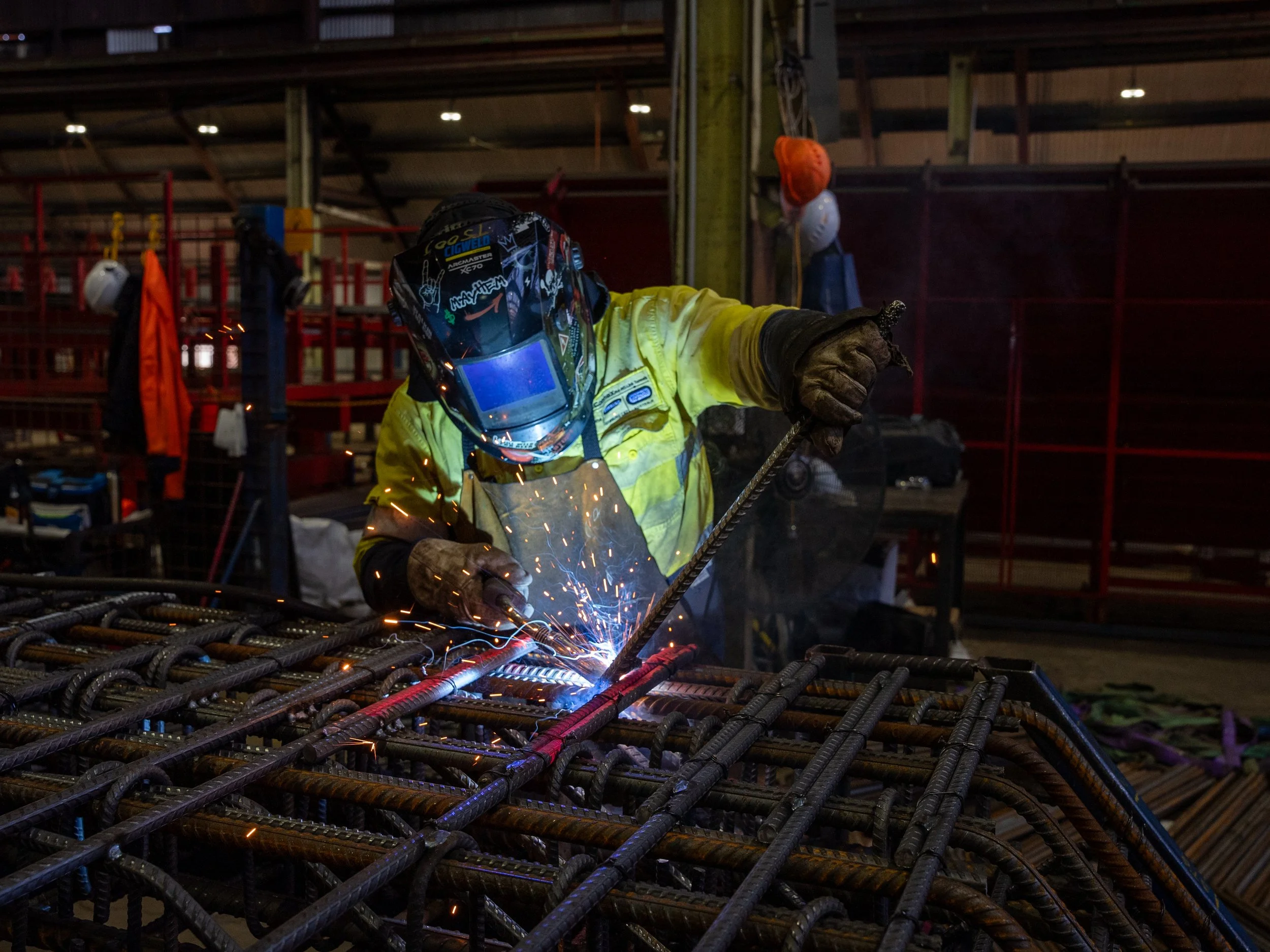

Offsite Prefabrication

Our in-house prefabrication capabilities offer significant advantages, including reduced bar congestion, improved on-site safety, faster installation, and simplified logistics. By fabricating reinforcement cages in a controlled factory environment, we ensure greater product quality, consistency, and efficiency. Prefabricated elements can be built and stored well in advance of installation, helping to reduce material waste, minimise weather-related delays, and streamline project delivery.

Cage Manufacturing

We manufacture a wide range of prefabricated reinforcement cages, including pile cages, beams, columns, pads, and diaphragm walls. Each unit is engineered and welded by our certified welders to meet project design specifications and reinforced as required for safe lifting and transport. Our in-house systems provide individual tagging for every cage, streamlining identification and ensuring efficient on-site installation.

Labour and plant hire

Our highly experienced workforce is available for flexible hire, offering steelfixers, formwork carpenters, concrete placement specialists, skilled labourers, and machine operators. All personnel are available on an hourly rate basis and can be deployed across interstate projects Australia-wide, ensuring responsive and reliable support for construction demands at any scale.

Modularised Reinforcement

We relocate complex reinforcement work from the unpredictable site environment to our controlled factory setting. This approach significantly improves safety, ensures high-quality outcomes through precision fabrication, and reduces the risk of weather-related delays. By delivering ready-to-install modules, we streamline installation, minimise on-site labour and crane time, and help reduce overall project disruption.

Accelerate your build, not your risk

Modularised Construction

We shift complex reinforcement from the unpredictable worksite to our controlled factory. This move fundamentally enhances site safety, guarantees superior quality through precision fabrication, minimising inclement weather risk and accelerates your project by delivering ready-to-install modules that reduce on-site labour, crane time, and disruption.

Road Infrastructure

- Bridges

- Tunnels

- Culverts

- Abutments

- Piles

- Capping Beams

- D-Walls

- Tunnel Elements

- Corbels

Rail Infrastructure

- Bridges

- Tunnels

- Culverts

- Abutments

- Piles

- Capping Beams

- Tunnel Elements

- Corbels

Marine Infrastructure

- Wharves

- Jetties

- Capping Beams

- Deck Slabs

- Fenders

- Crossheads

- Beams

Water/Wastewater

- Footings

- Piles

- Bunds

- Storage Facilities

- Tank Bases

Mining and Resources

- Footings

- Bunds

- Sumps

- Capping Beams

Energy and Renewables

- Tower Footings

- Foundations

- Building & Substation Foundations

Commercial Highrise

- Piles

- Footings

- D-walls

- Columns

- Shafts

- Beams

X-Press Service

Carrabay’s X-Press Service resolves urgent reinforcement challenges with speed and certainty. We cut and bend rebar to specification and deliver directly to site, often within 24 hours of order placement, supporting scheduled pours and preventing costly delays.

Our production facilities and in-house expertise enable rapid turnaround without compromising quality. By coordinating closely with clients and managing detailing, fabrication, and delivery under one roof, we eliminate miscommunication, reduce downtime, and keep projects moving.